Hardware

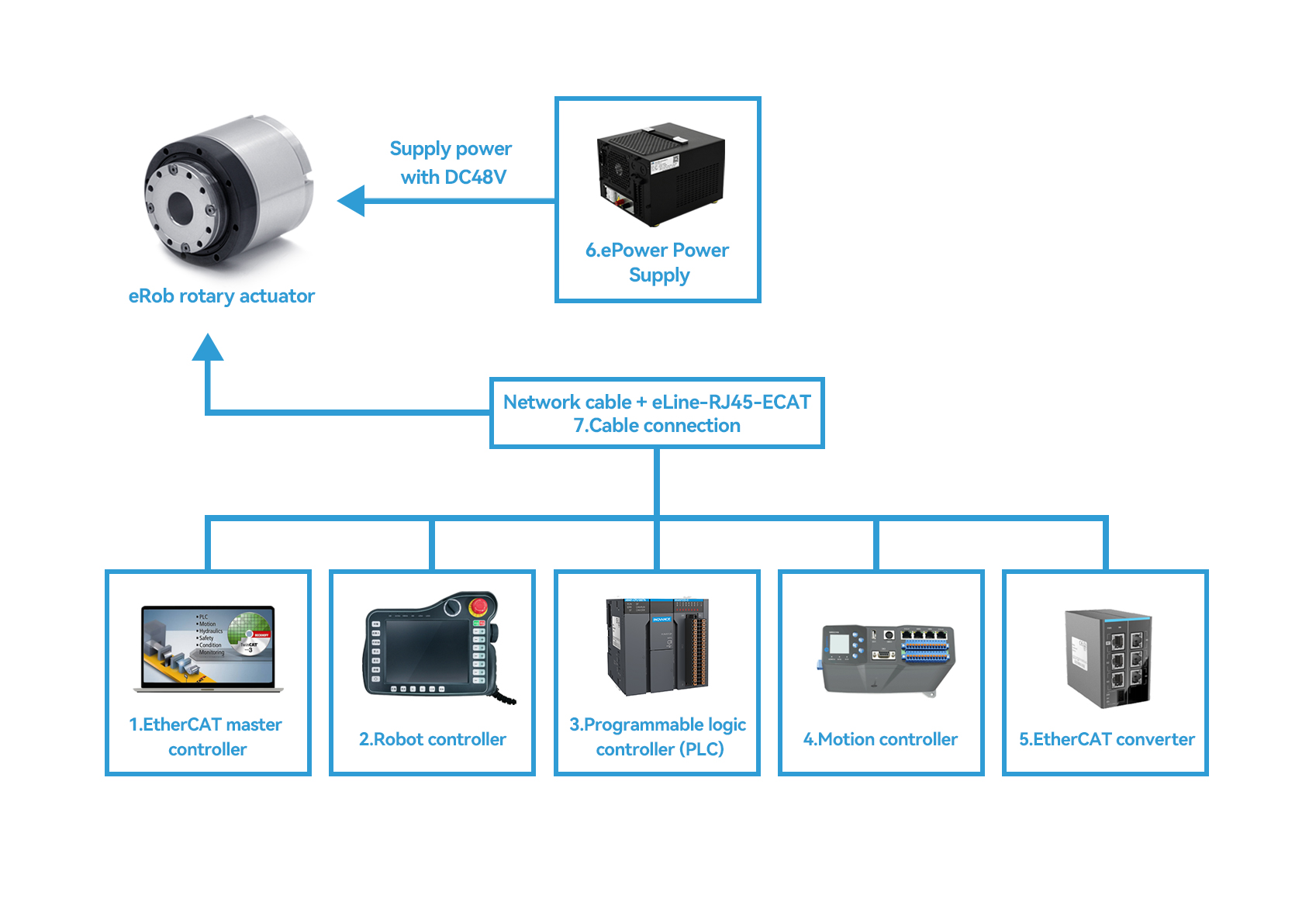

eRob integrates two communication interfaces: one is CAN, and the other is EtherCAT. The CAN interface is mainly used for joint debugging, while EtherCAT serves as the primary communication method, capable of running a control cycle at up to 2000Hz, which meets the requirements of most industries. In this example, we provide instructions on how to drive eRob in different modes using TwinCAT3 via the EtherCAT protocol.

This development kit supports the controllers of many well-known manufacturers at home and abroad, allowing you to easily overcome the problems encountered in the process of building robot hardware and communication protocol stacks, and efficiently complete robot application development.